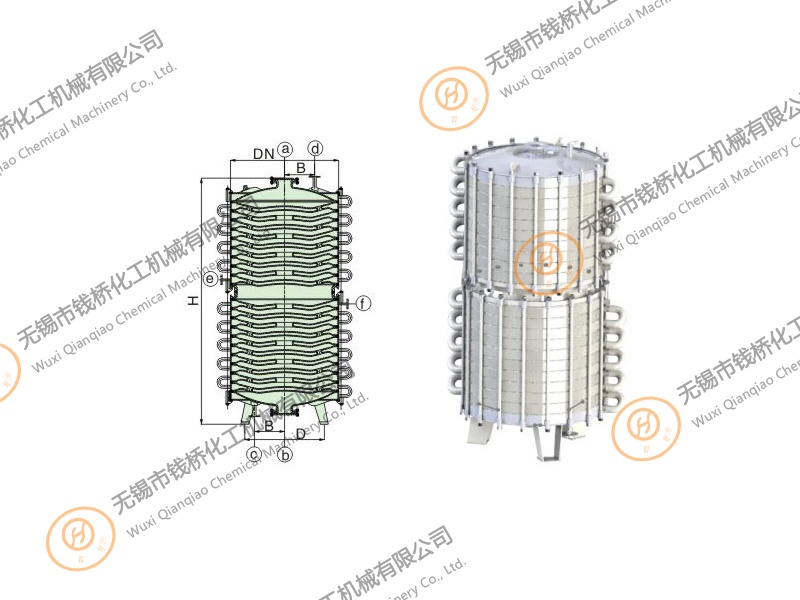

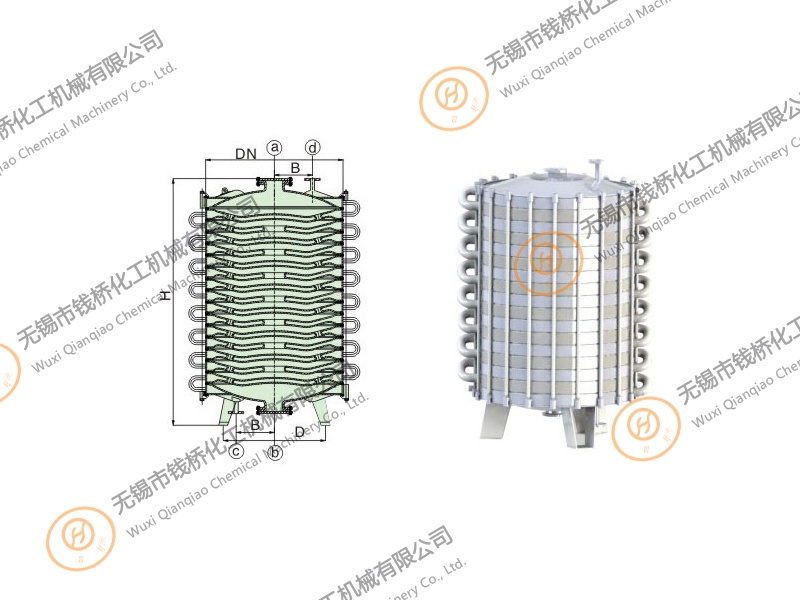

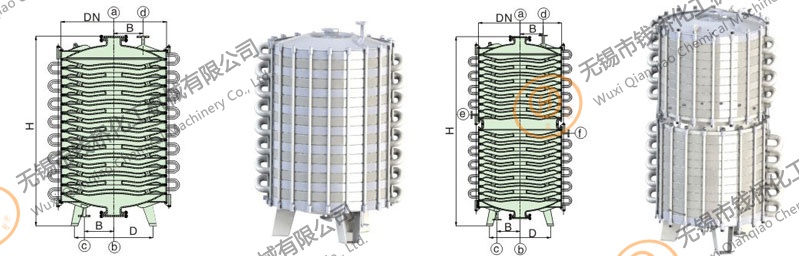

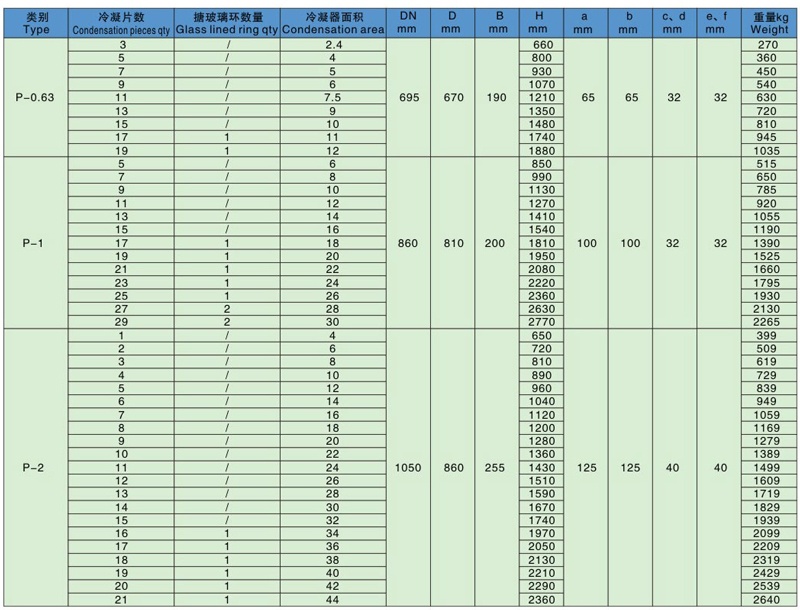

P series Glass Lined Plate Condenser

P series Glass Lined Plate Condenser:The new mould and welding process are adopted to ensure the sealing and internal pressure bearing capacity of the equipment, no porcelain explosion and no leakage, simple and easy to use, and high cost performance.

P series Glass lined plate

type condenser

1.Design prdssure:Vessel FV-0.1mpa,Interlayer 0.3mpa;

2.Design temperature:200℃;

3.Executive standard:HG/T4298-2019;

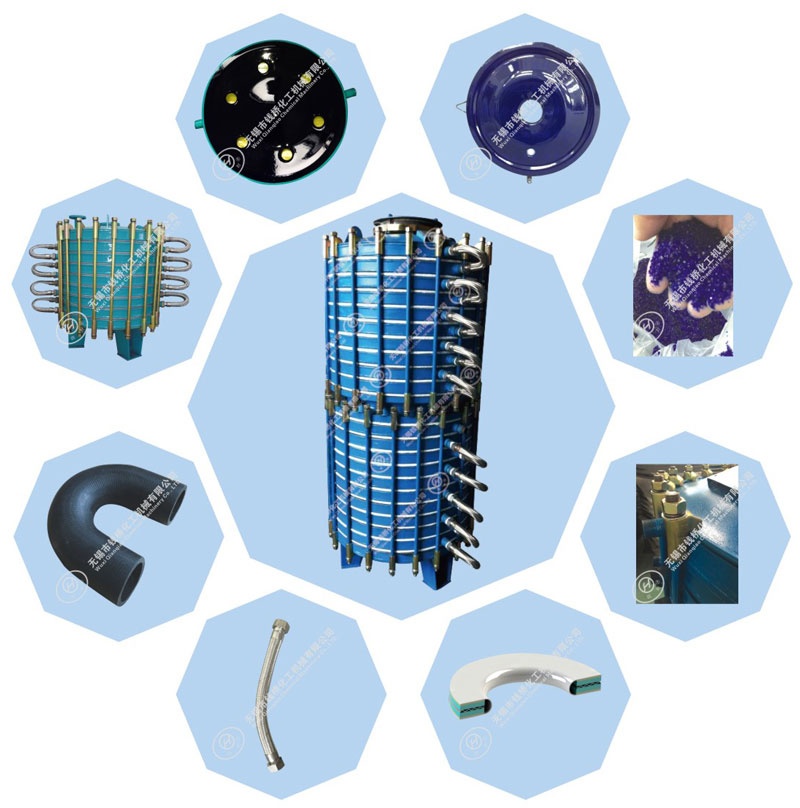

Glass-lined new chip condenser Gescription:

Performance characteristics:

1.This product can handle in addition to hydrofluoric acid,phosgene,concentrated phosphoric acid (concentration>30%,temperature> 150℃),intensity ( PH >12 ) and temperature > 100℃everything all chemical fluoride ionsoutside the media.

2.Small size, light weight, compact, hot air and cooling water through the reverse flow of heat exchange.

3.After a certain period of use after the event of damage to components, may replace or reduce the single partial,will not cause the whole retirement or discontinued, the Director of the machine greatly the service life.

4.I plant a new piece of glass lined condenser can withstand full vacuum limit, and difficult to furring, and compared to similar glass-lined chip condensers, heat exchange rate can be increased by 30% to 50%.

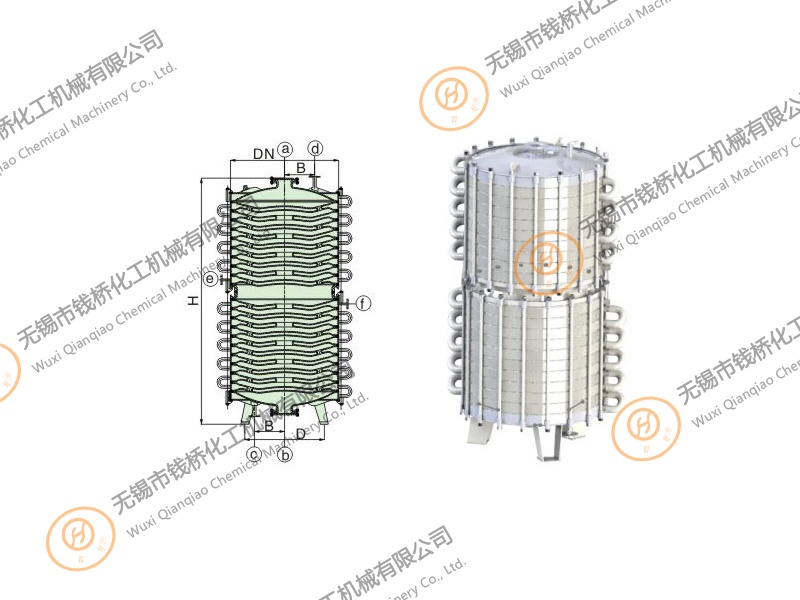

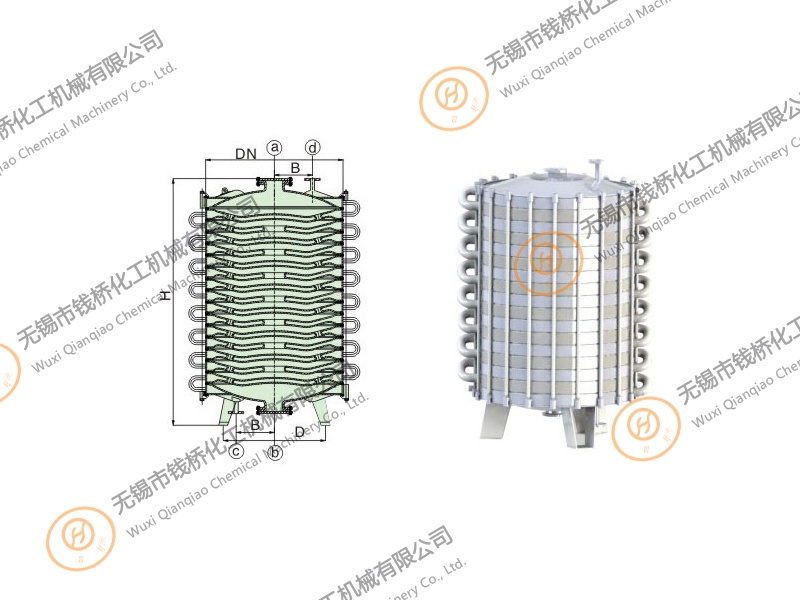

5.I plant a new piece of glass lined condenser sub-NW-0.63-and NW-1 type two. In addition each model is divided into two holes and six holes of two specifications.

Precautions for use:

1 .The use of pressure:vacuum inside the limits of tolerance or≤0.1 Mpa, laminated pressure≤0.2Mpa. (If any special requirements, need to inform the company before ordering )

2. Glass-lined thermal shock temperature≤110℃, cold shock temperature difference≤100℃.

3. The company’s glass-lined piece is different from the conventional condenser design than specific products, all rigorously tested before shipmemt, the disintegration of your customers do not arbitrarily disassemble, otherwise the Company shall not be responsible for any problems

please notify the company, I the company will send technical personnel on-site service.

Instructions:

1 .The product to the end, cover, and a number of condensed films, supplemented washers, studs, nuts assembled, assembly drawings and related requirements should be.

2. Hot air from the Ministry of holes into the lid, the bottom of the hole out of the condensate. Over into the cooling water from the bottom, cover the Department to take over outflow. Acrossing to the over outflow of water temperature and condenser exit temperature to regulate the flow of cooling water in order to further improve the condensing efficiency.

3. Cooling water should be controlled in a neutral PH value, not less than 6, usually between 6 to 8, or lrongut to hydrogen adsorption, can cause a large area of glass lining layer peeling off, the water should be relatively clean, to prevent impurity deposition.

4. Use the event of partial disclosure, may be appropriate to tighten the nut parts, but not too tight.

5. In use should be first on the cooling water through the hot air after the termination should stop using the hot air, after the cessation of cooling water.

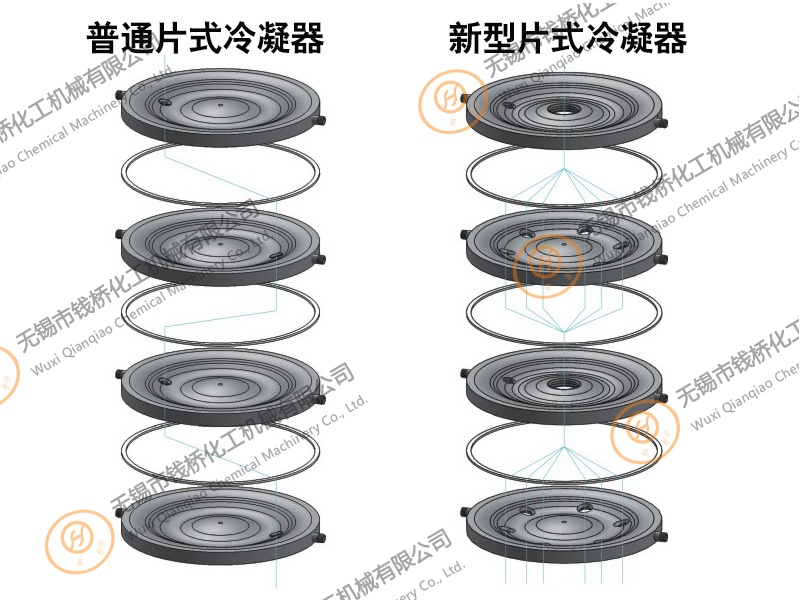

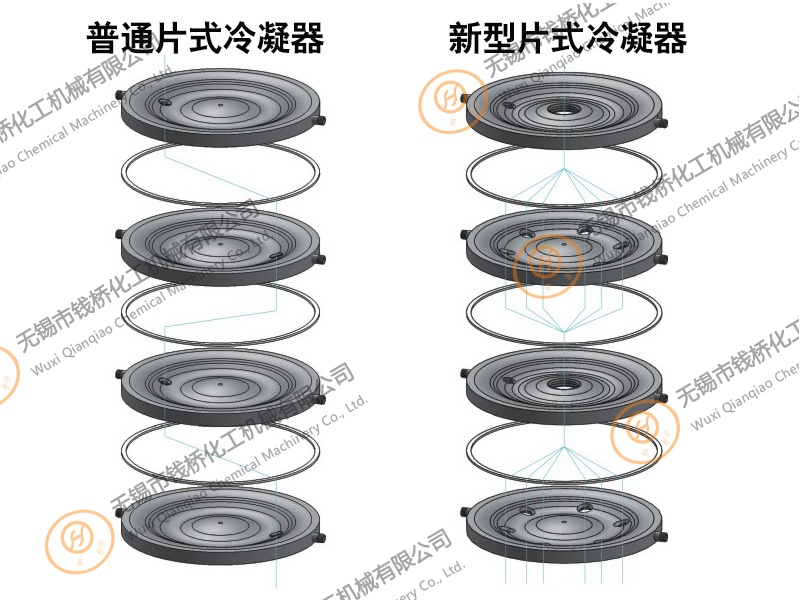

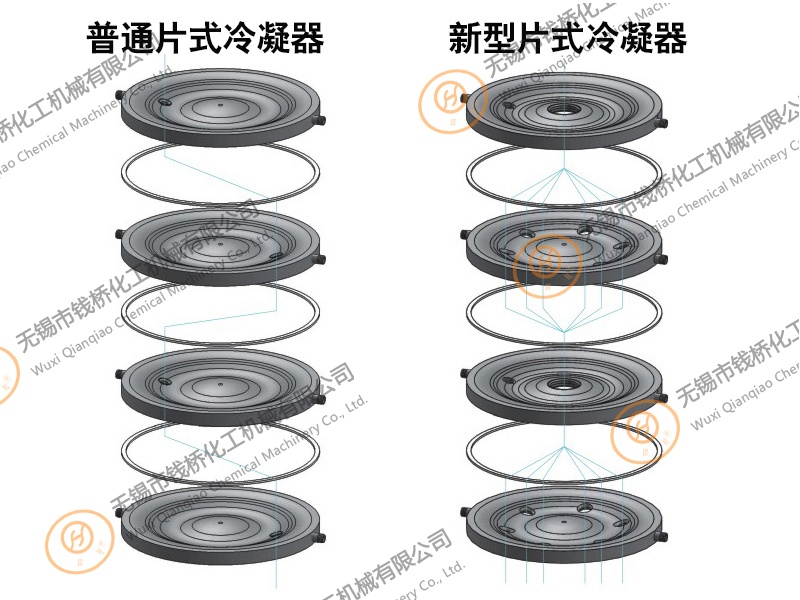

Glass lined plate type condenser and the ordinary type condenser performance

The ordinary type condenser performance

1.Small single hole on the plate (180°cross on every plate ) increase the resistance of liquid, gas distributing is not equal, easy flows partially, it is inavailabe in heavy vacuum.

2.Single plate is thick, cooling water flows slowly, furring is produced easily, heat excahange efficiency is low.

3.Thichness of gasket are more than 20mm generally, sweel and shrink largely, Become deformation easily and resist pressure lowly, vacuum sealing is inavailable.

Glass lined plate type condenser

1.DTD model platetype condenser is developed and improved on disadvantages of common plate

condenser.lt can be used on havey vacuum distillation and evcaporation device, improves pressure falling, solves the leakage problem.

2.Single plate is thicher than common condenser's, cooling water flows fast, liquid distributes

equally because of 6 holes on plate.Comparing with the same area condenser,heat exchange

efficiency is increased more than 50%,furring is produced hardly.

3.Thichness of gaskets are 10mm,sweel and thrink lightly,resist pressure highly,vacuum sealing

is available.

Application of glass lined condenser:

Enamel condenser is a kind of general process equipment widely used in petroleum, chemical, petrochemical, metallurgy, electric power, light industry, food and other industries. In oil refining and chemical plants, the condenser accounts for about 40% of the total equipment and 30% ~ 45% of the total investment. In recent years, with the development of energy-saving technology and the continuous expansion of application field, the use of condenser for high-temperature and low-temperature heat recovery has brought significant economic benefits. Condenser is a typical process equipment, which is widely used in any chemical production process.