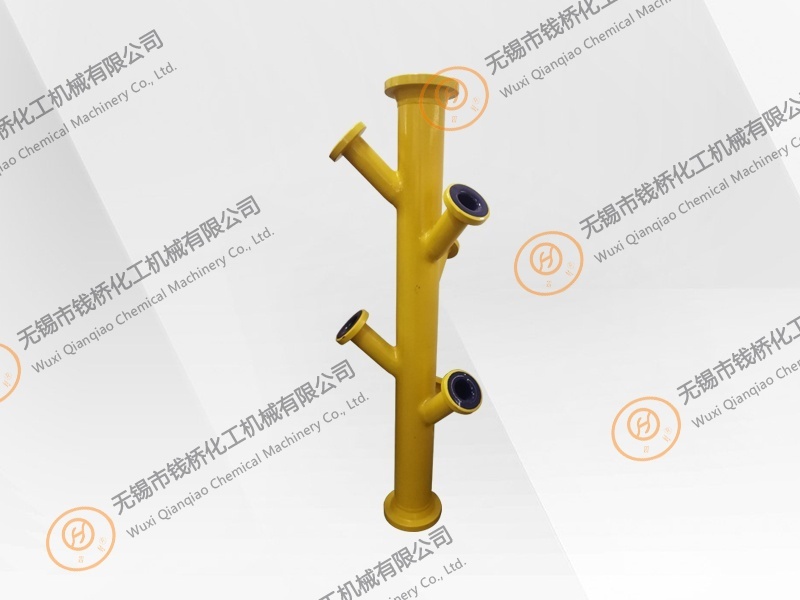

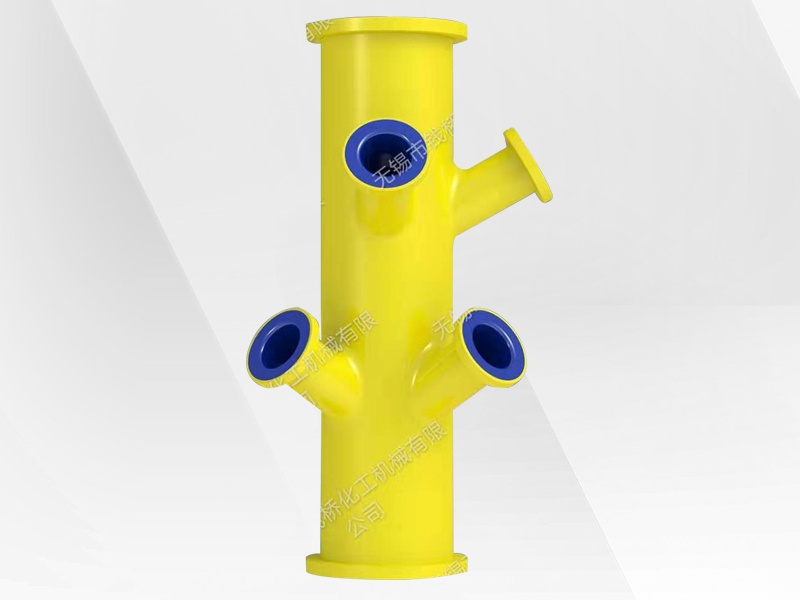

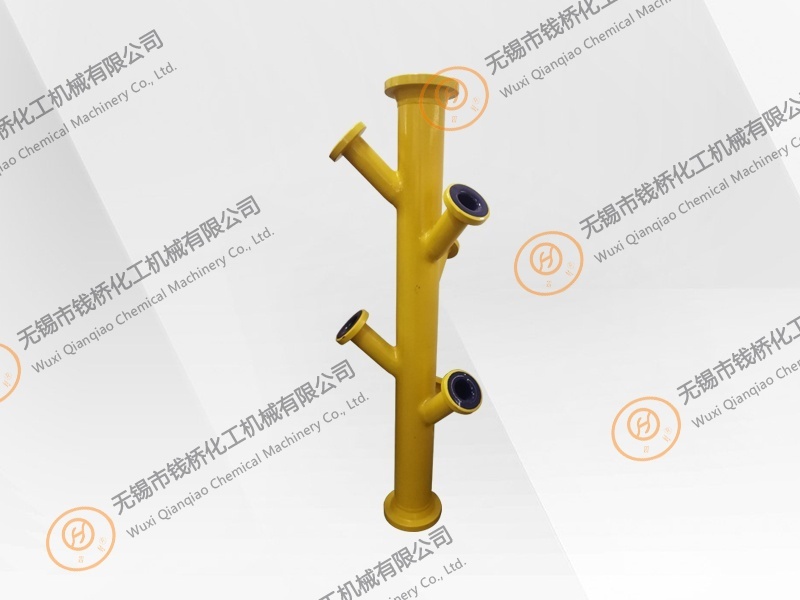

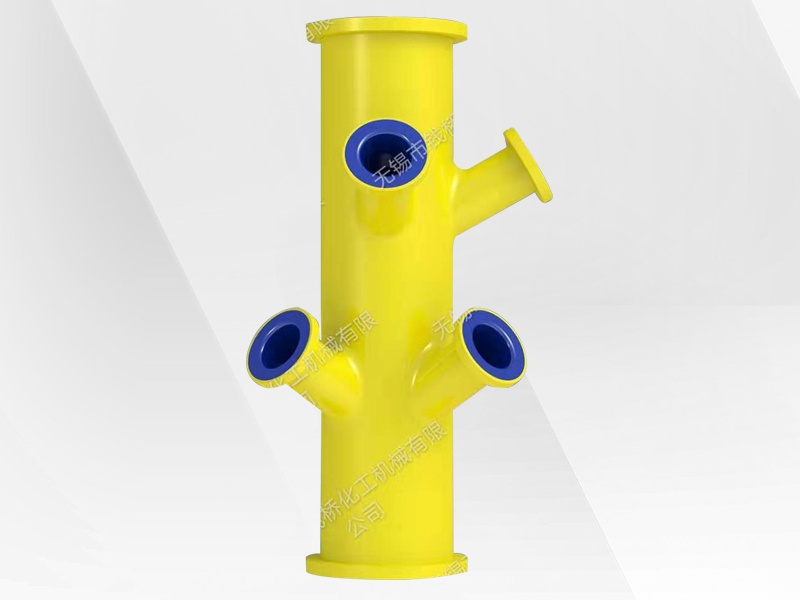

Glass lined inclined nozzle distributor

Advantages of glass lined inclined nozzle distributor produced by Qianqiao Chemical Machinery Co., Ltd.:

1) It can produce small DN25 ~ DN2000 glass lined pipe fittings and tower sections (DN250 and below are generally within 3000mm; DN300 and above can be up to 4000mm), and relevant glass lined accessories.

2) All glass lined inclined nozzle distributors adopt the cold spraying process. The cold spraying requires the workers to repeatedly grind and refine the blank and glass lined glaze powder, and the water in the glass lined glaze powder is dry. Under the operation of the technology, the glass lined feeding pipe is fired many times, the thickness of the porcelain layer is uniform, the glass lined layer is closely combined with the metal matrix, and it is not easy to appear the phenomenon of dark bubbles and the whole porcelain surface falling off.

3) Qianqiao chemical machinery plant is the world's leading manufacturer of enameling technology, which can produce more stringent European standards and DIN standards in line with national standards.

4) Qianqiao chemical machinery factory has established a long-term cooperative relationship with the famous European enamel factories to purchase the world-class enamels for a long time, which ensures that the Fired Glass Enamels can be used stably for a long time under adverse conditions such as chloroacetic acid.

The glass lined pipe fitting is a component of spraying the glass lined glaze containing silicon on the surface of the metal steel embryo, baking at a high temperature of about 900 ℃, so that the glass lined glaze is closely combined with the metal matrix, and a layer of glass layer with a thickness of 0.8-2mm is evenly distributed on the surface of the metal matrix. Pipe fitting is an important component of material transmission. The surface of glass lining layer of glass lining pipe fitting is bright and clean, with chemical stability similar to that of glass. It can withstand the corrosion of all inorganic and organic acids except hydrofluoric acid and thermal phosphoric acid. It can withstand the dissolving action of all organic solvents. Compared with glass pipe fittings, the metal of glass lined pipe fittings basically has enough rigidity and strength, which can avoid the secondary damage caused by the brittle failure of similar glass pipe fittings. Compared with steel lined tetrafluorocarbon pipes, due to the close combination of glass lined layer and metal matrix, it will not be like steel lined tetrafluorocarbon even under high temperature and vacuum conditions The non-metallic layer of the pipe falls off like that. Therefore, glass lined pipes are widely used in chemical industry, petrochemical industry, medicine, dyestuff, pesticide, food manufacturing, national defense and other industrial production and scientific research for their excellent performance, playing an irreplaceable important role.

Glass lined pipe assemblies can be divided into two categories: the first category is composed of steel lined glass lined pipes, which constitute the main body of glass lined pipe assemblies, such as glass lined pipes, elbows including 30 °, 45 °, 60 °, 90 °, 180 ° elbows, tees (including equal diameter tees and reducing tees), cross (including equal diameter tees and reducing tees), reducer (including concentric reducer, eccentric reducer Diameter pipe, reducing flange), distance piece and flange cover, etc.; the second type is the connection and sealing component made of non glass lined material, For example, the looper flange, gasket, fastener (including bolt, nut, washer) of glass lined equipment; its function is to complete the combination and assembly between glass lined pipe fittings or between glass fittings and other pipes (equipment), so as to realize the function of pipes as a whole.

Pipe fitting is an important component of material transmission. The surface of glass lining layer of glass lining pipe fitting is bright and clean, with chemical stability similar to that of glass. It can withstand the corrosion of all inorganic and organic acids except hydrofluoric acid and thermal phosphoric acid. It can withstand the dissolving action of all organic solvents. Compared with glass pipe fittings, the metal of glass lined pipe fittings basically has enough rigidity and strength, which can avoid the secondary damage caused by the brittle failure of similar glass pipe fittings. Compared with steel lined tetrafluorocarbon pipes, due to the close combination of glass lined layer and metal matrix, it will not be like steel lined tetrafluorocarbon even under high temperature and vacuum conditions The non-metallic layer of the pipe falls off like that. Therefore, glass lined pipes are widely used in chemical industry, petrochemical industry, medicine, dyestuff, pesticide, food manufacturing, national defense and other industrial production and scientific research for their excellent performance, playing an irreplaceable important role.