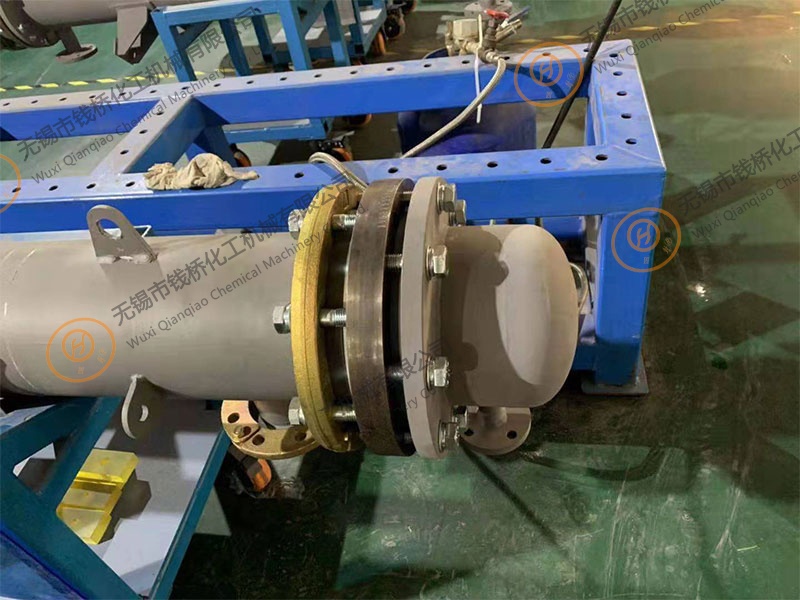

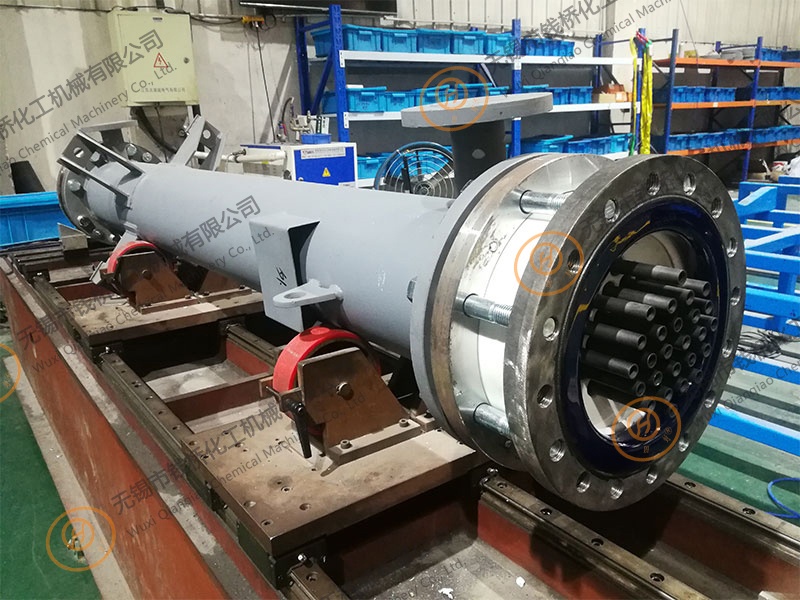

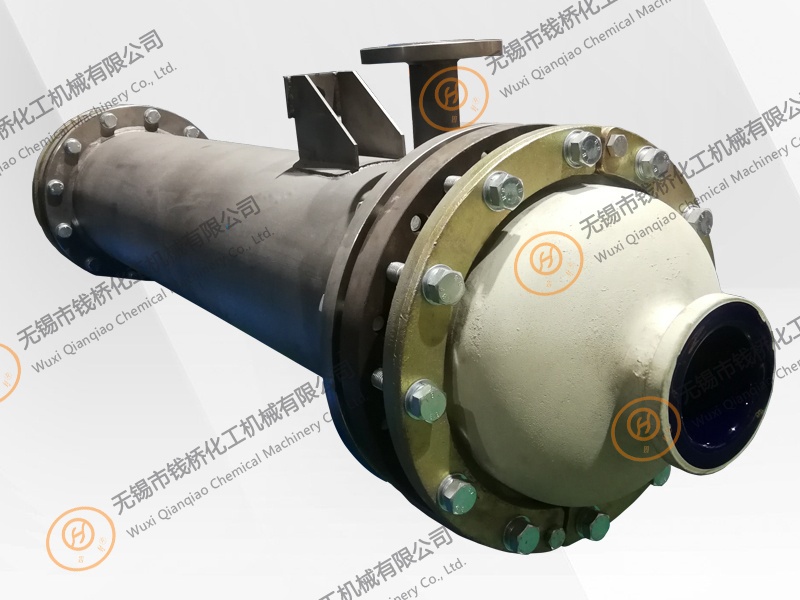

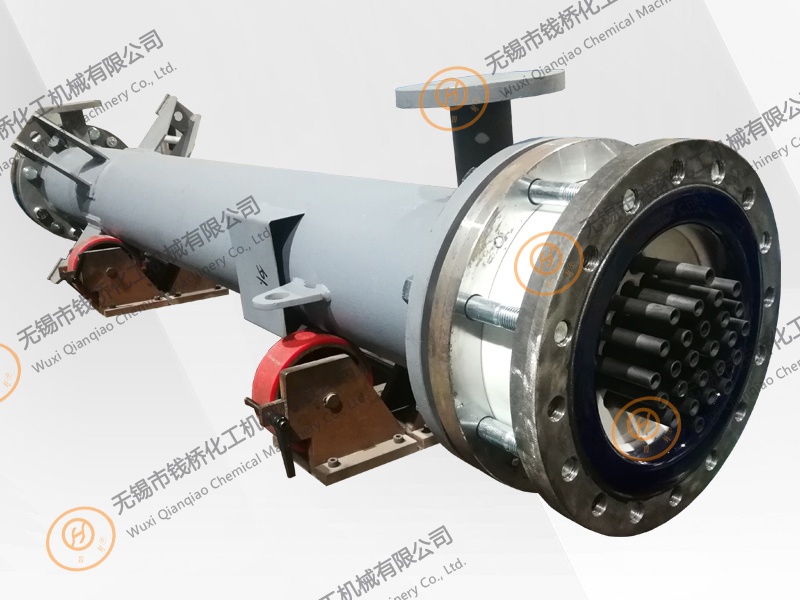

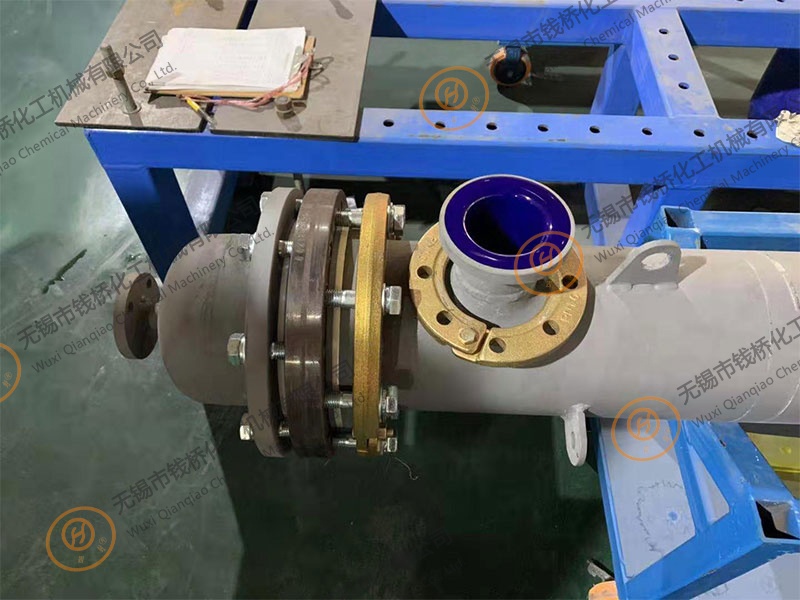

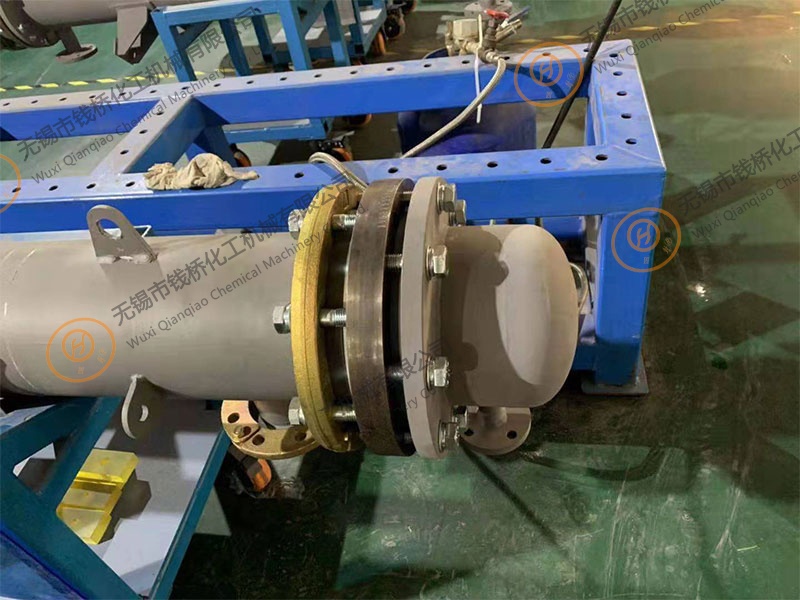

Double tube SIC heat exchange

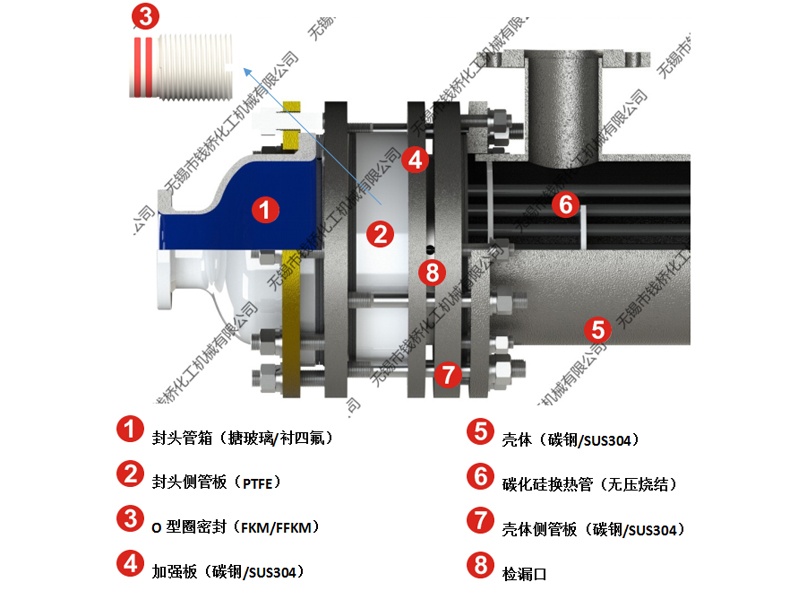

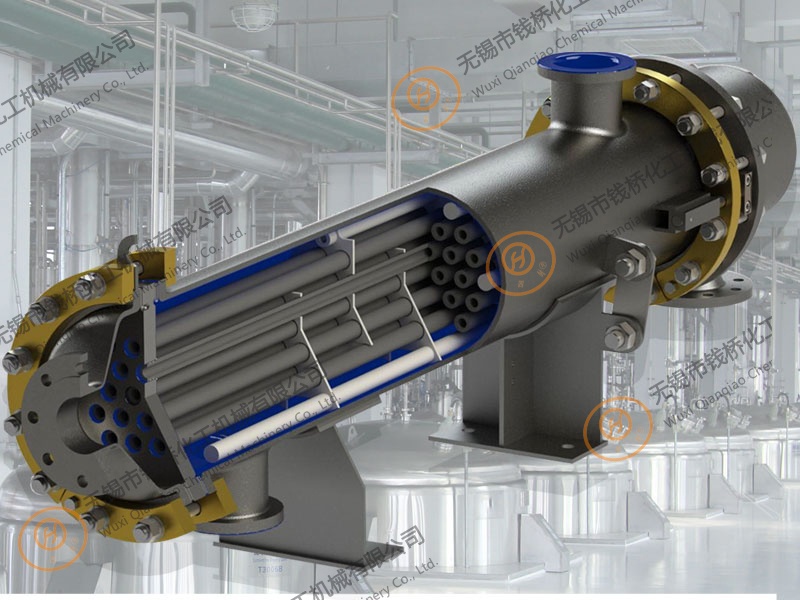

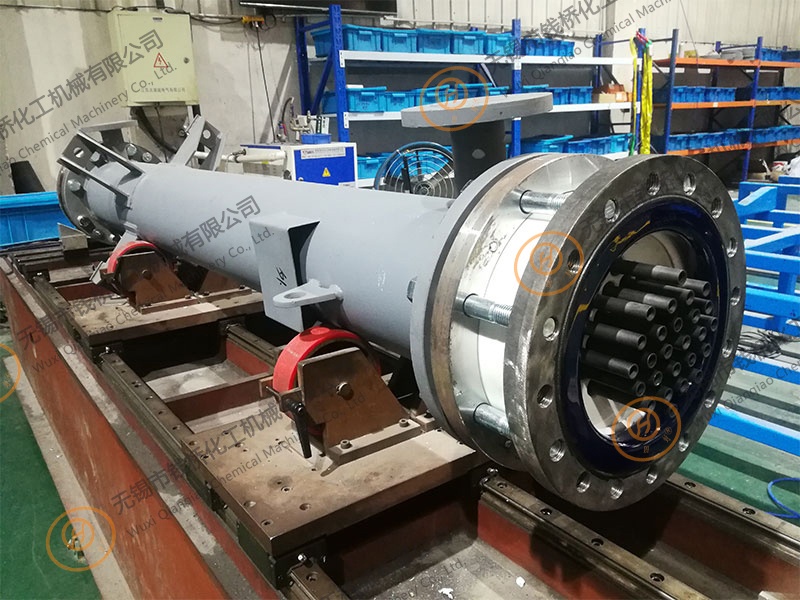

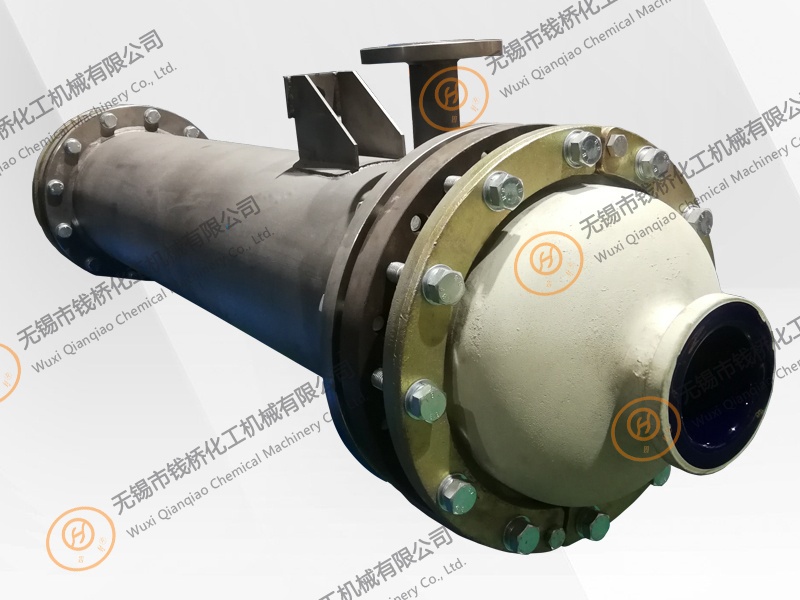

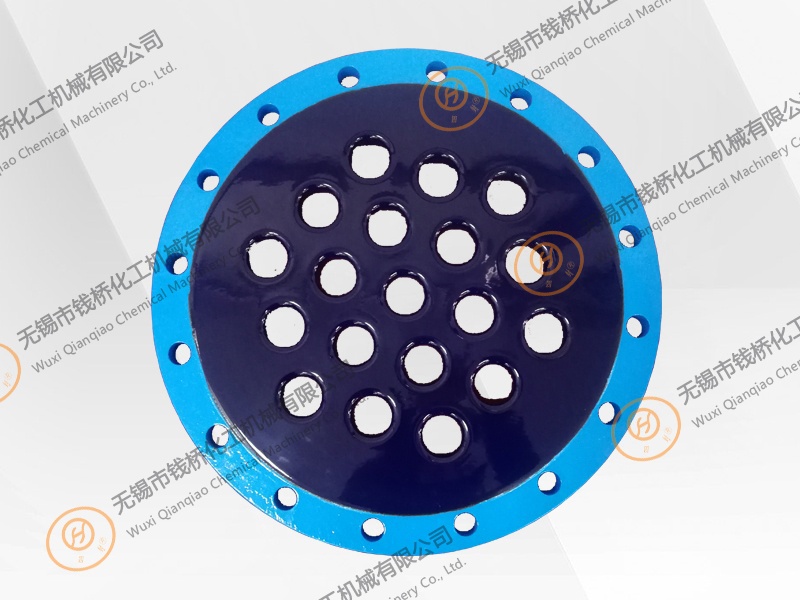

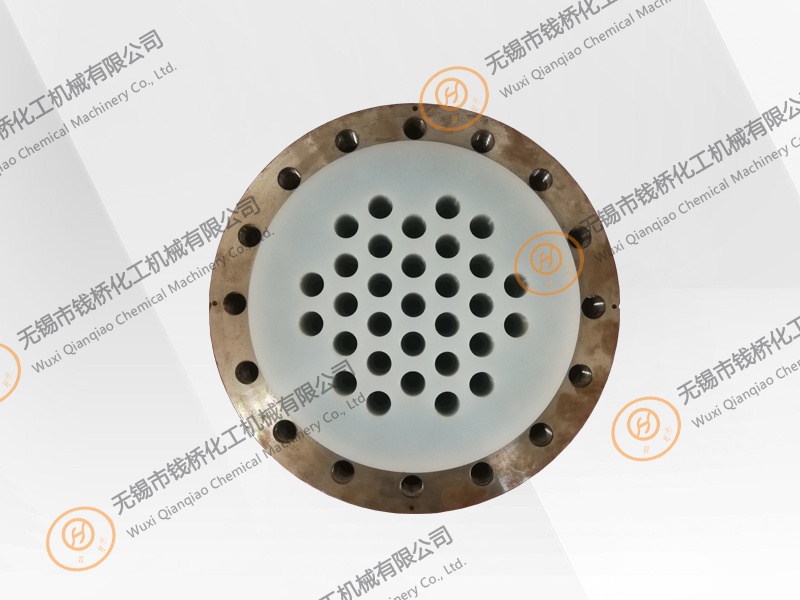

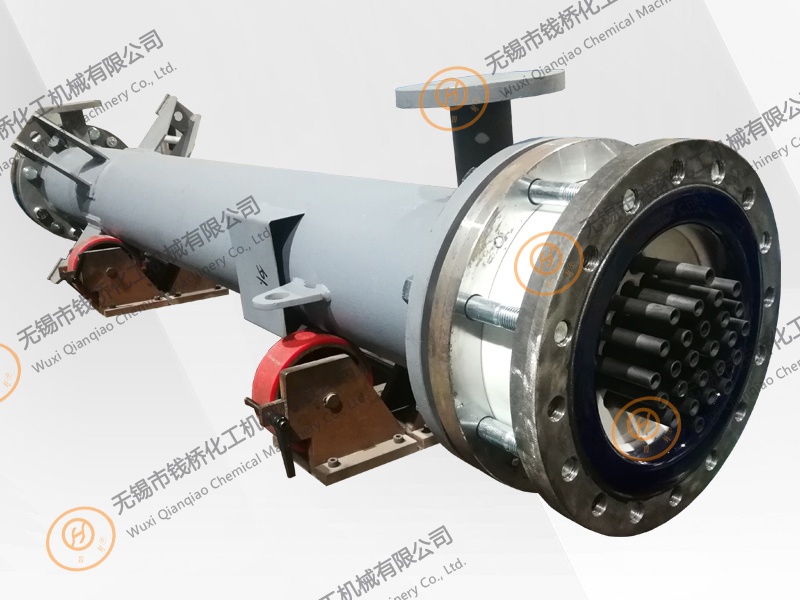

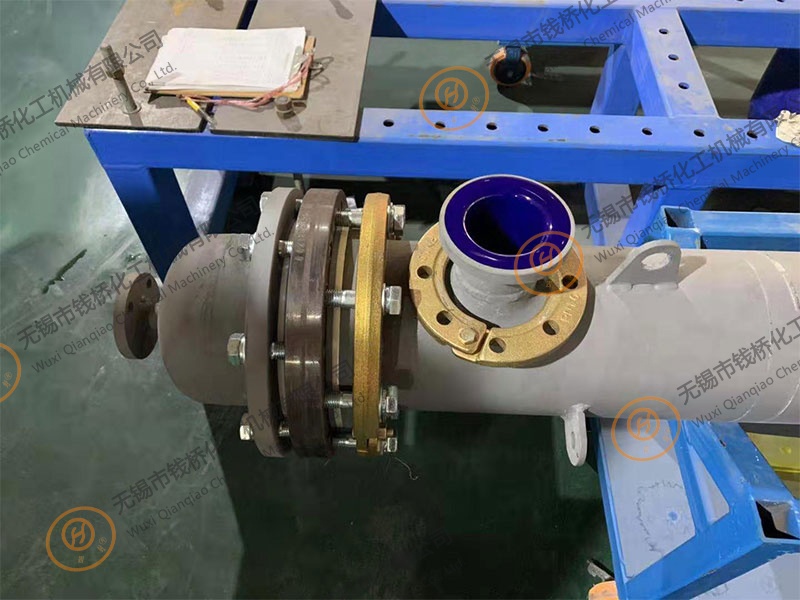

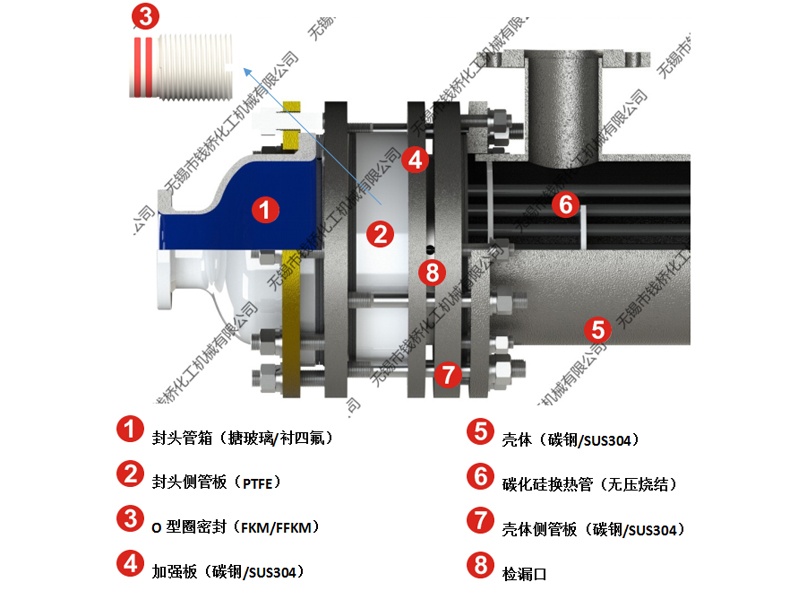

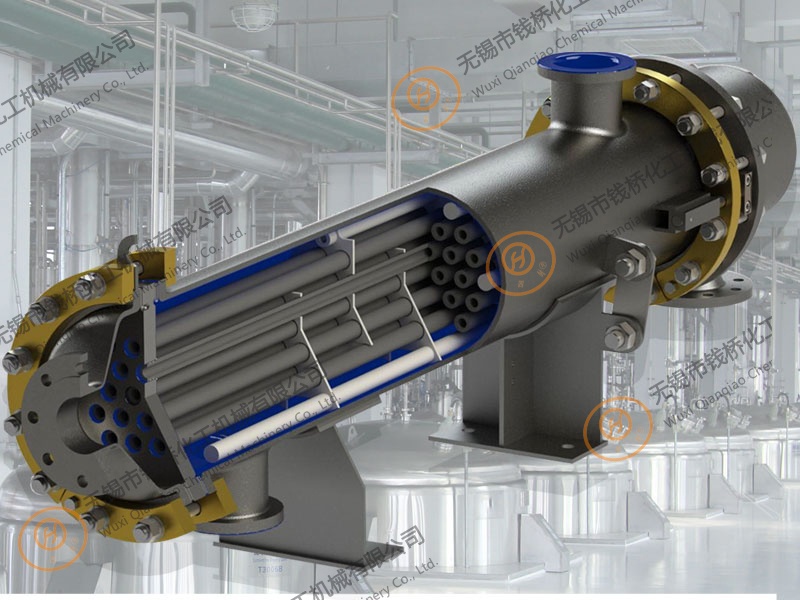

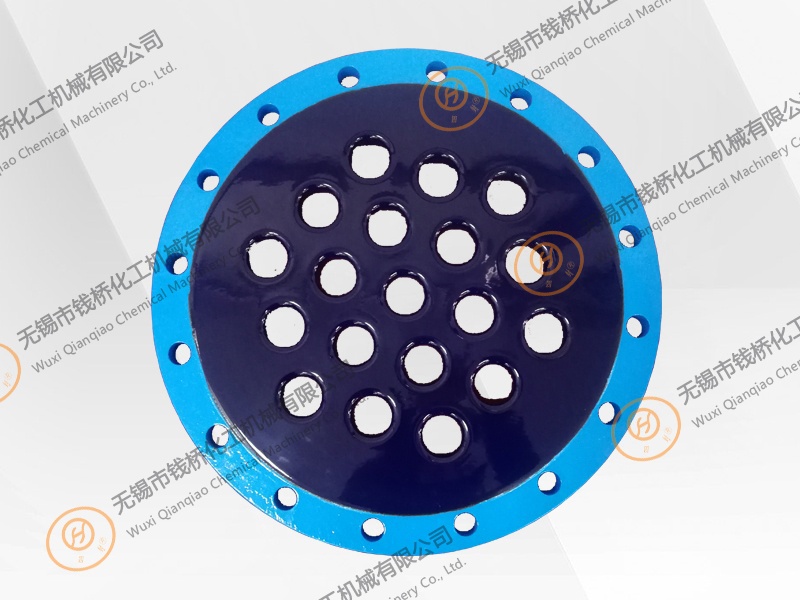

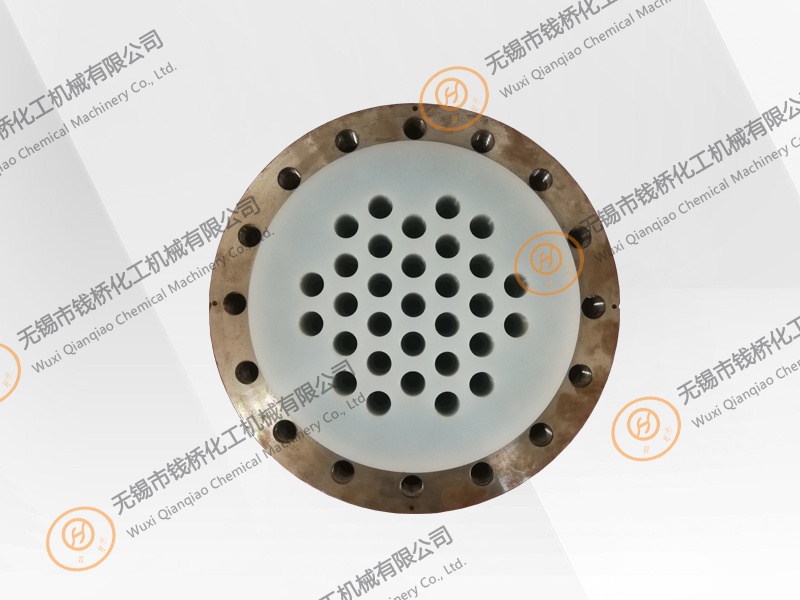

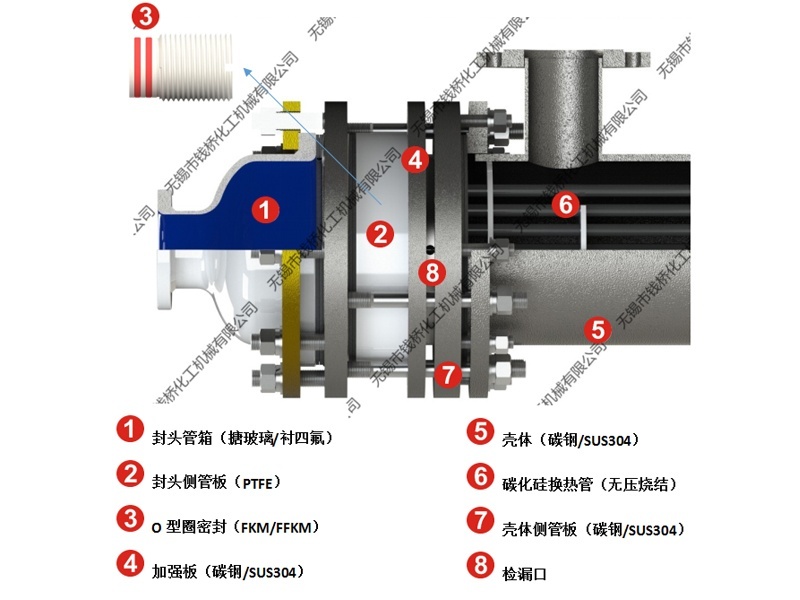

SIC tube heat exchanger, consisting of corrosion-resistant tube sheets and silicon carbide tubes, is the best solution for the most demanding corrosive conditions.

SIC tubular heat exchangers use heat-resistant tubes made of corrosion-resistant silicon carbide that are ideal for heating, cooling and condensing chemically corrosive process media. Typical applications include: bromine, sulfuric acid, hydrofluoric acid, nitric acid, hydrochloric acid and other acids; bases; halogenated compounds; salt solutions and organic compounds.

Double tube SIC heat exchange

● Test each heat exchange tube under pressure of 185 Bar before installation

● Heat exchanger housing diameter range from DN100 to DN600

● The standard length of the heat exchange tube is 1000 to 3000mm

● Heat exchange area is 1 to 60 square

● Heat exchange tube diameter is 14mm and 19mm

● Horizontal or vertical installation

● Applicable temperature range -19℃ to 100℃

● Applicable pressure range -0.1Mpa to 0.6Mpa

● Comply with CE, ATEX, FDA

● Double tubeSheet deSign

It is possible to separate the process fluid and the service fluid with a separation chamber, so that in case of o-ring leaking no mix will occur between the two fluids.

Red column must be filled Click to download

|

Design requests of SIC |

|||||

|

Device number |

|

|

|||

|

|

|

Jacket |

in side of heat exchanger |

||

|

Fluid name / component |

|

|

|

||

|

Total flow |

kg/h |

|

|

||

|

Gas flow |

kg/h |

|

|

||

|

Liquid flow |

kg/h |

|

|

||

|

Non condensable material flow |

kg/h |

|

|

||

|

Tempreture ( In / Out) |

°C |

|

|

|

|

|

Freezing point / Boiling point |

°C |

|

|

||

|

Density |

kg/m3 |

|

|

||

|

Viscosity |

cP |

|

|

||

|

Gas molecular weigh |

g/mol |

|

|

||

|

Molecular weight of non condensates |

g/mol |

|

|

||

|

Specific heat |

cal/g/k |

|

|

||

|

Thermal conductivity |

kcal/m/K/h |

|

|

||

|

latent heat |

kcal/kg |

|

|

||

|

Inlet pressure (absolute pressure) |

Mpa |

|

|

|

|

|

Current Speed |

m/s |

|

|

||

|

Pressure drop |

bar |

|

|

||

|

Fouling coefficient |

kcal/h/m2/°C |

|

|

||

|

Heat exchange capacity |

kcal/h |

|

|||

|

Heat transfer coefficient(clean / dirty / service side) |

kcal/h/m2/°C |

|

|||

|

Corrected logarithmic mean temperature difference |

°C |

|

|||

|

Heat exchange area (required / provided) |

m2 |

|

|||

|

Equipment selection data |

|||||

|

Design temperature |

°C |

|

|

||

|

Design pressure |

barg |

|

|

||

|

Test pressure |

barg |

|

|

||

|

Process number |

|

|

|

||

|

Inlet pipe diameter |

mm |

|

|

||

|

Outlet pipe diameter |

mm |

|

|

||

|

Material |

|

|

|

||

|

Weight (empty / full water) |

kg |

|

|||

|

Installation method |

|

|

|||

SIC tubular heat exchangers use heat-resistant tubes made of corrosion-resistant silicon carbide that are ideal for heating, cooling and condensing chemically corrosive process media. Typical applications include: bromine, sulfuric acid, hydrofluoric acid, nitric acid, hydrochloric acid and other acids; bases; halogenated compounds; salt solutions and organic compounds.